Description

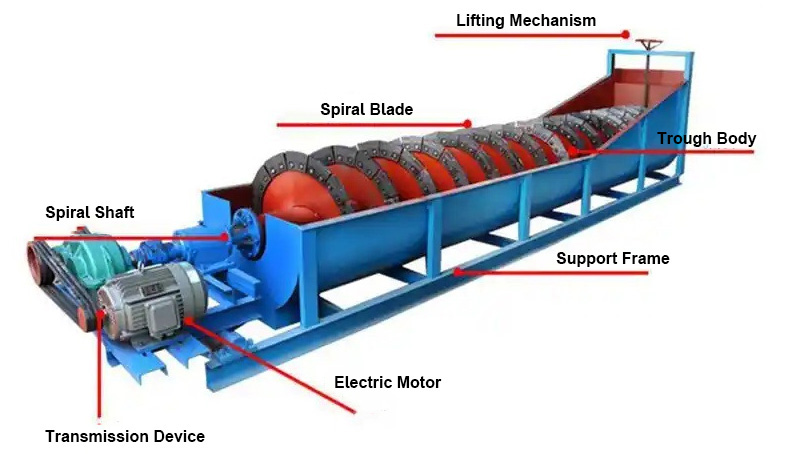

Spiral Sand Washing Machine

Product Parameters

| Name | Spiral sand washing machine |

|---|---|

| Keyword | Sand washer |

| Application | Sand washing, mineral classification |

| Feeding Particle Size | 40mm |

| Motor Power | 15kw |

| Weight | 3t |

| Tank Type | Concurrent flow tank |

| Cyclone Type | Hydrocyclone |

Support customization of various sizes.

If you have any other requirements, please contact us

Working Principle

Superior Cleaning Performance for Premium Quality Sand

This advanced equipment delivers exceptional cleaning results through its unique design. Specifically, the spiral mechanism combines mechanical agitation with optimized water flow. This dual-action approach removes dirt and impurities effectively. Consequently, you obtain sand with extremely low clay content. The final product consistently achieves high purity levels. Moreover, this processing method meets strict construction standards perfectly. It ensures uniform quality output throughout operations. Your construction projects therefore gain access to superior materials. Ultimately, your project quality improves significantly. The system maintains this outstanding performance daily. Your production quality remains consistently excellent.

Robust Construction and Reliable Operation

The equipment features a compact yet durable design. Particularly, the central spiral shaft utilizes high-strength materials. These components demonstrate excellent wear resistance. Furthermore, operational downtime remains minimal. Maintenance procedures are straightforward and simple. This configuration supports continuous operation effectively. You can run the system for extended periods reliably. Daily operations experience fewer disruptions. As a result, your production schedule maintains perfect reliability. The equipment’s durability guarantees long-term service. You enjoy years of trouble-free performance.

Energy Efficiency and Cost-Effective Operation

This system consumes significantly less energy. It outperforms other washing methods economically. Additionally, water recycling efficiency reaches impressive levels. The innovative design reduces fresh water consumption dramatically. You save substantially on utility expenses. Operating costs decrease remarkably over time. This approach ensures excellent economic performance. Your production becomes more sustainable. Therefore, your business gains crucial competitive advantages. These savings continue throughout the equipment’s lifespan.

High Capacity Processing for Maximum Productivity

A single unit handles impressive volumes per hour. Capacity ranges from tens to hundreds of tons. This perfectly matches large-scale production needs. You achieve greater output effortlessly. The system enhances complete workflow efficiency. Overall productivity improves substantially. Your operation meets market demands easily. Consequently, profitability increases steadily. The equipment manages peak loads seamlessly. You eliminate concerns about capacity limitations.

Wide Compatibility and Versatile Applications

This equipment processes diverse materials successfully. It handles river sand with excellent results. It cleans mountain sand effectively. Similarly, it processes crushed stone sand thoroughly. Integration with jaw crushers works seamlessly. Cooperation with sand making machines is perfect. Furthermore, connection to vibrating screens is smooth. This configuration suits complete production lines ideally. Your plant setup gains maximum flexibility. Therefore, you manage various projects effortlessly. The system adapts to your specific operational requirements perfectly.

Reviews

There are no reviews yet.