Description

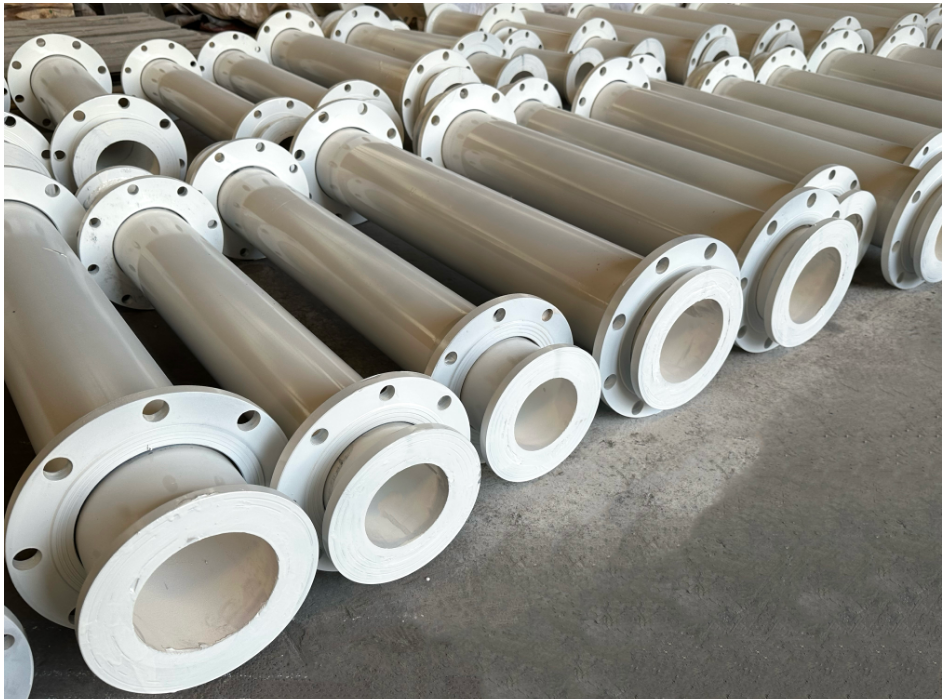

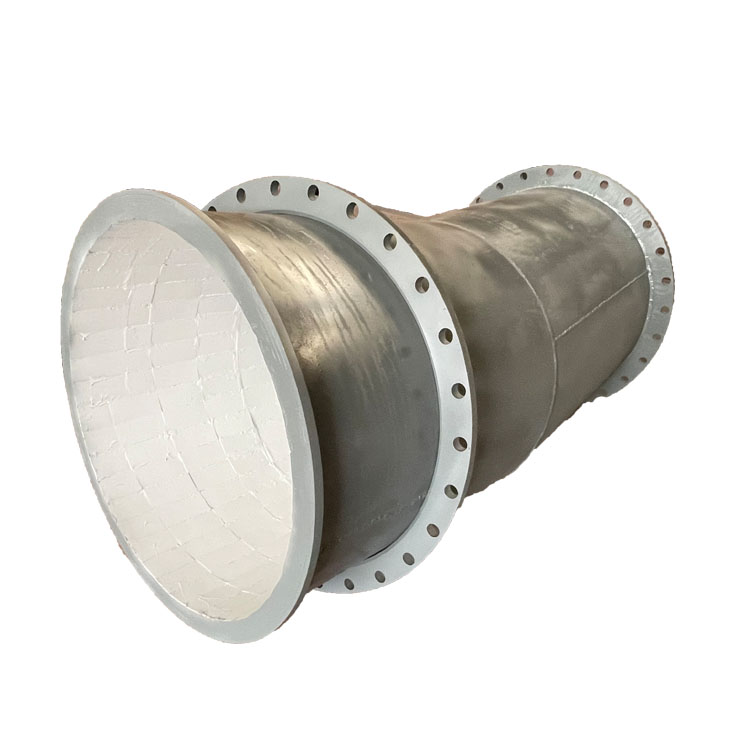

Ceramic Patch Wear-resistant Pipe

| Specification | Outer diameter | Inside diameter | Wall thickness | Steel pipe thick |

|---|---|---|---|---|

| DN80 | 112~132 | 80 | 10~14 | 6~12 |

| DN100 | 132~152 | 100 | 10~14 | 6~12 |

| DN125 | 157~177 | 125 | 10~14 | 6~12 |

| DN150 | 182~202 | 150 | 10~14 | 6~12 |

| DN200 | 236~264 | 200 | 10~20 | 6~12 |

| DN250 | 286~314 | 250 | 10~20 | 6~12 |

| DN300 | 336~364 | 300 | 10~20 | 6~12 |

| DN350 | 386~414 | 350 | 10~20 | 6~12 |

| DN400 | 436~464 | 400 | 10~20 | 6~12 |

| DN450 | 486~514 | 450 | 10~20 | 6~12 |

| DN500 | 542~584 | 500 | 15~30 | 6~12 |

| DN600 | 642~684 | 600 | 15~30 | 6~12 |

| DN700 | 742~784 | 700 | 15~30 | 6~12 |

| DN800 | 842~884 | 800 | 15~30 | 6~12 |

| DN900 | 942~984 | 900 | 15~30 | 6~12 |

| DN1000 | 1046~1088 | 1000 | 15~30 | 8~14 |

| DN1200 | 1246~1288 | 1200 | 15~30 | 8~14 |

| DN1400 | 1446~1488 | 1400 | 15~30 | 8~14 |

| DN1600 | 1646~1688 | 1600 | 15~30 | 8~14 |

| DN1800 | 1846~1888 | 1800 | 15~30 | 8~14 |

| DN2000 | 2046~2088 | 2000 | 15~30 | 8~14 |

Key Features of Ceramic Patch Wear-resistant Pipe

The Ceramic Patch Wear-resistant Pipe offers exceptional wear resistance due to its high-alumina ceramic lining. This lining provides extreme hardness for prolonged service life. It lasts five to ten times longer than standard steel pipes. Moreover, the pipe withstands high impact and pressure effortlessly. Its sturdy steel shell and strong bonding ensure durability. Additionally, the pipe is lightweight and easy to install. This reduces overall project time and costs. Furthermore, the smooth inner surface minimizes friction. It prevents clogging and enhances material flow. Also, the pipe resists corrosion and high temperatures effectively. Thus, it suits various harsh industrial conditions. These features make it a reliable choice for abrasive material handling.

Ideal Applications and Use Cases

This pipe excels in multiple industrial settings. For example, it is perfect for coal processing plants. It handles heavy-medium coal slurry pipelines with ease. Moreover, it serves mining operations for ore conveyance. Additionally, power plants use it in ash handling systems. Furthermore, steel mills apply it in material transfer chutes. Also, ports and terminals rely on it for bulk material transport. Therefore, it covers sectors like metallurgy and cement production. In each case, it boosts efficiency and reduces downtime. So, consider it for any high-wear application to maximize productivity.

Why Choose Our Ceramic Patch Wear-resistant Pipe

Our Ceramic Patch Wear-resistant Pipe comes from years of expertise in slurry pump manufacturing. We ensure top-quality materials and precise engineering. Moreover, we offer customized solutions to meet specific needs. Additionally, our products undergo rigorous testing for reliability. Furthermore, we provide excellent customer support and after-sales service. Also, our competitive pricing delivers great value. Therefore, partnering with us means investing in longevity and performance. Choose our pipe for proven results and industry trust.

Project

Contact Us

In summary, the Ceramic Patch Wear-resistant Pipe delivers durability, efficiency, and versatility. It addresses common issues in abrasive material transport. Moreover, it supports various industries with reliable performance. Additionally, our commitment to quality ensures satisfaction. Therefore, upgrade your systems with this advanced solution today. Furthermore, contact us for more details or to place an order. Let’s work together to enhance your operational success.

Reviews

There are no reviews yet.